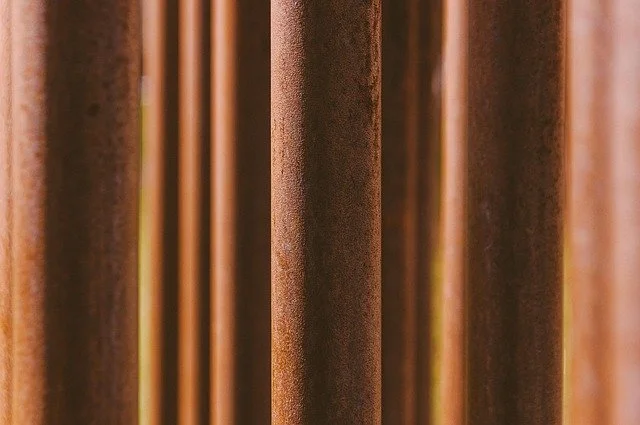

Steel and Brass Pipes Benefit Most from EN Coatings

/Metal parts manufacturers producing long tubes, cylinders, and pipes for fluid handling understand that corrosion rarely begins only on the outside surface. In many applications, especially in chemical processing, oil and gas, and industrial fluid transport, the interior of a pipe is exposed to aggressive media, high pressure, and temperature fluctuations. Without proper protection on both the inner diameter and external surfaces, structural degradation can occur rapidly, leading to leaks, contamination, or catastrophic failures. Internal coatings must provide consistent thickness and adhesion throughout the full length of the component, while exterior coatings protect against environmental exposure, mechanical abrasion, and oxidation.

Unfortunately, not all finishing processes deliver uniform coverage across complex geometries or long internal passages. Conventional electroplating methods can struggle to maintain consistent thickness inside narrow tubes due to uneven current distribution. Powder coating, while effective on external surfaces, is typically unsuitable for long internal diameters because it is difficult to achieve full coverage without voids or thin spots. Thermal spray coatings and certain dip-coating techniques may also leave inconsistent layers in deep cavities or long bores. For manufacturers requiring reliable metal plating for steel pipes, selecting a process capable of reaching all surfaces is critical for long-term performance and durability.

How Electroless Nickel Coating Achieves Uniform Coverage

Electroless nickel plating provides a unique alternative to traditional electroplating because it does not rely on an electrical current to deposit material. Instead, the coating forms through a controlled chemical reduction process that deposits a uniform nickel-phosphorus layer across all exposed surfaces. Because the process is autocatalytic, the coating thickness remains consistent regardless of part geometry, making it ideal for long pipes, intricate channels, and deep internal diameters.

During the plating cycle, properly prepared components are immersed in a chemical bath where nickel ions bond evenly to the substrate. This process allows the coating to build uniformly across the inside diameter, outer surfaces, and even recessed features. For manufacturers working with specialty alloys or copper-based components, electroless nickel coating for brass provides excellent corrosion resistance, improved wear characteristics, and dimensional stability without the challenges associated with current-based plating methods. The resulting finish offers a smooth, dense layer that enhances both performance and longevity in harsh environments.

Electroless nickel is particularly effective when tight tolerances must be maintained. Unlike many conventional plating methods, the uniform deposition minimizes the need for post-processing or machining corrections. This makes it a reliable solution for precision assemblies used in chemical processing systems, oil and gas pipelines, and industrial fluid transfer equipment where internal coatings must remain consistent throughout the entire component length.

Why Ni-Carb Coating Excels in Oil and Gas Applications

Among the advanced formulations derived from electroless nickel technology, Ni-Carb coating has become a preferred solution for demanding applications involving steel pipes and brass barrels. Ni-Carb is engineered using silicon carbide particles embedded within a nickel Phosphorus matrix, creating a composite coating that delivers exceptional hardness, wear resistance, and corrosion protection. This unique structure allows the coating to withstand abrasive particles, corrosive fluids, and extreme operational conditions commonly encountered in energy sector infrastructure.

The performance advantages of Ni-Carb coating extend beyond durability. The embedded silicon carbide particles increase surface hardness while maintaining a uniform coating thickness throughout the part. This ensures that internal passages remain protected against erosion caused by high-velocity fluids or chemical reactions. In oil and gas environments, where components are frequently exposed to saline solutions, hydrocarbons, and abrasive contaminants, the added resilience of Ni-Carb significantly extends service life while reducing maintenance costs.

Manufacturers seeking reliable metal plating for steel pipes often turn to specialized finishing providers that understand the complexities of internal coatings. An experienced pipe coating company in TX, for example, may offer tailored electroless nickel and composite coating solutions designed specifically for long tubular components. These providers possess the equipment necessary to process extended lengths while maintaining strict control over coating thickness, bath chemistry, and surface preparation.

Maintenance considerations are equally important when evaluating coating strategies. Pipes and tubular components operating in corrosive environments may require periodic inspection and reconditioning to maintain optimal performance. Selecting a coating formulation that allows for consistent refurbishment without compromising dimensional accuracy helps extend the overall lifespan of the equipment.

When applied correctly, advanced electroless nickel formulations deliver uniform protection across internal and external surfaces, ensuring that both structural integrity and operational efficiency are maintained. For manufacturers producing high-performance fluid transport systems, choosing the right coating method is as critical as selecting the proper base material.

Metal parts manufacturers must consider coating technologies that can address complex geometries and long internal dimensions without sacrificing consistency or durability. Traditional finishing processes may fall short when uniform internal coverage is required, making electroless nickel and Ni-Carb coatings valuable solutions for modern industrial applications. By working with experienced surface coating suppliers and specialized equipment manufacturers, companies can achieve reliable corrosion resistance, extended service life, and enhanced performance across demanding fluid transport environments.